Partlow

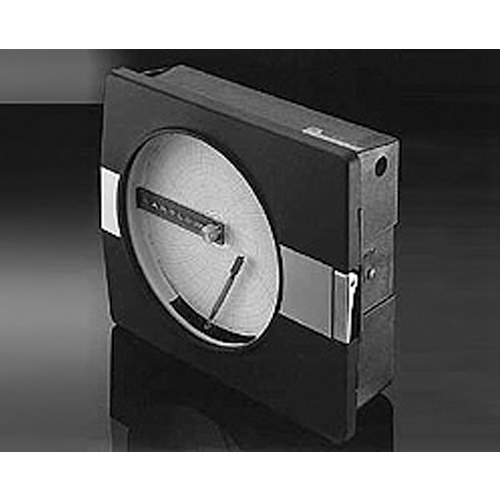

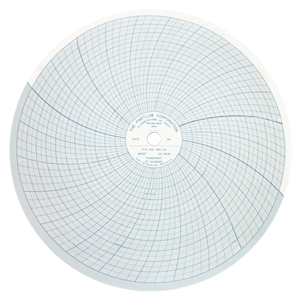

For over 25 years, FLW, Inc. has been a proud stocking distributor of Partlow Instruments providing a line of temperature controllers, temperature recorders & accessories including recorder charts & pens.

Partlow recorders and controllers are ubiquitous in the manufacturing industry. They have been a leader in instrumentation design and manufacture with products that include indicators, controllers, setpoint programmers and recorders which handle process variables such as temperature, pressure, level and flow.

Please contact FLW, Inc for application or commercial assistance for any Partlow product.