Limited Availability

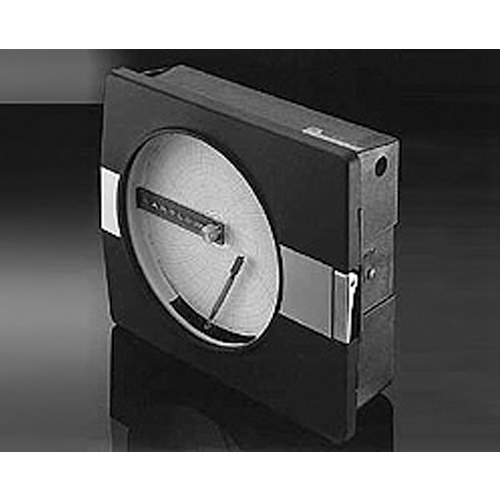

Contact FLW for available optionsPartlow RF Series Mechanical Recorders

Partlow mechanical recorders are popular in process and automation industries.

The 8” recorders are the leading recording device in the refrigerated transport industry. Partlow offers one and two pen 10” circular chart industrial temperature recorders. The spring wound chart driver instruments require no operating power. This makes Partlow mechanical recorders an excellent choice for varied applications. The control capability is similar to mechanical controllers and can also be used for alarm.

Models

- RFT Recording Thermometer

- RF15-79 Recording Temperature Control

- RFA Pneumatic Recording Temperature Control

- RFP Modulating Temperature Recorder

- RFHTT Modulating Temperature Recorder

- RFH15-79 / RFH15-15 Dual Mechanical & Switch Recording Temperature Control

- RFHAA Dual Recording Pneumatic Temperature Control

- RFC15-52 Recording & Controlling Dual Switch Temperature Programmer

- RFCP Recording &Controlling Potentiometric Temperature Programmer

- RFC52 Recording & Controlling Temperature Switch Programmer